ABR Plastic P2 Air

No. 075520001

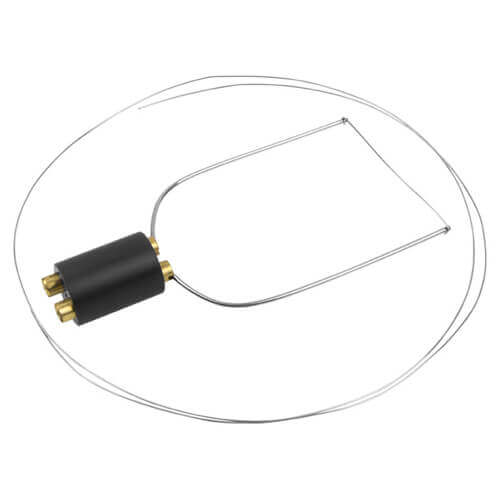

Professional compact electrical equipment for repairs and welding of plastic materials.

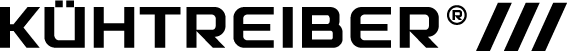

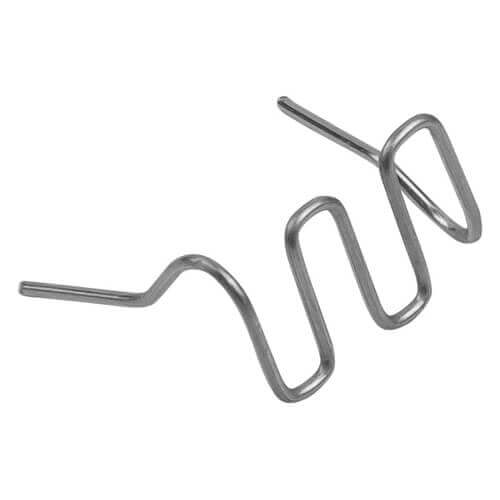

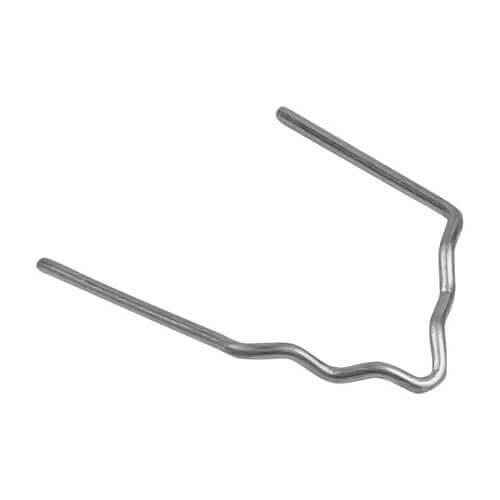

The device is equipped with burners for working with shaped staples and hot air intended for welding. Shaped staples are used for reinforcement cracks. Using hot air and additional plastic materials it is possible to weld plastic materials or fill holes.

Hot air is generated by an integrated compressor or by an external gas (nitrogen). The staple, inserted into the holes in the burner, is after switching on the heating, it heats up very quickly and can be pushed into the damaged one places of plastic part. The connection can be further modified with special melting knives, which allow final finishing by smoothing damaged area. After the materials have cooled, a resilient, elastic and durable joint is created.

The device saves on the replacement of expensive spare parts and reduces the impact on the environment. Thanks to its wide range of applications, the machine is a perfect helper in automotive and engineering and the plumbing industry, in maintenance or assembly

FEATURES AND EQUIPMENT

- high performance and efficiency

- low weight and small dimensions

- light signalization

- heating temperature setting

- reliable construction

- starting kit (cutting / melting knives – straight and bended, gas nozzle bended, staple holder, additional material – PP / PE / ABS, steples – various shapes)

| Supply voltage 50/60 Hz | 1× 230 V ±15 % |

| Protection - slow | 16 A |

| Input current | max. 3 A |

| Duty cycle max. (40 °C) | 75 A (melting knife) |

| Duty cycle max. (40 °C) | 12 A (staple) |

| Gas temperature | max. 500 °C |

| Air flow - internal input | 15 l/min. |

| Air flow - external input | 12 - 20 l/min. |

| Protection class | IP 20 |

| Dimensions | 280 x 175 x 130 mm |

| Weight | 15 kg |

ABR Plastic P2 Air

No. 075520001

Professional compact electrical equipment for repairs and welding of plastic materials.

The device is equipped with burners for working with shaped staples and hot air intended for welding. Shaped staples are used for reinforcement cracks. Using hot air and additional plastic materials it is possible to weld plastic materials or fill holes.

Hot air is generated by an integrated compressor or by an external gas (nitrogen). The staple, inserted into the holes in the burner, is after switching on the heating, it heats up very quickly and can be pushed into the damaged one places of plastic part. The connection can be further modified with special melting knives, which allow final finishing by smoothing damaged area. After the materials have cooled, a resilient, elastic and durable joint is created.

The device saves on the replacement of expensive spare parts and reduces the impact on the environment. Thanks to its wide range of applications, the machine is a perfect helper in automotive and engineering and the plumbing industry, in maintenance or assembly

FEATURES AND EQUIPMENT

- high performance and efficiency

- low weight and small dimensions

- light signalization

- heating temperature setting

- reliable construction

- starting kit (cutting / melting knives – straight and bended, gas nozzle bended, staple holder, additional material – PP / PE / ABS, steples – various shapes)

| Supply voltage 50/60 Hz | 1× 230 V ±15 % |

| Protection - slow | 16 A |

| Input current | max. 3 A |

| Duty cycle max. (40 °C) | 75 A (melting knife) |

| Duty cycle max. (40 °C) | 12 A (staple) |

| Gas temperature | max. 500 °C |

| Air flow - internal input | 15 l/min. |

| Air flow - external input | 12 - 20 l/min. |

| Protection class | IP 20 |

| Dimensions | 280 x 175 x 130 mm |

| Weight | 15 kg |