Handheld Laser 3in1

Fiber laser welding is increasingly expanding across materials and applications.

Innovations in laser technology and beam transmission components overcome traditionally challenging laser welding applications such as welding copper, dissimilar materials, thin metal foils or poorly matched parts.

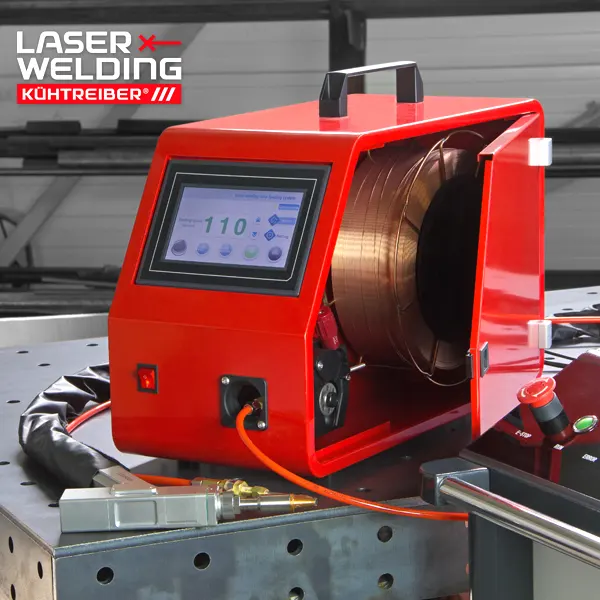

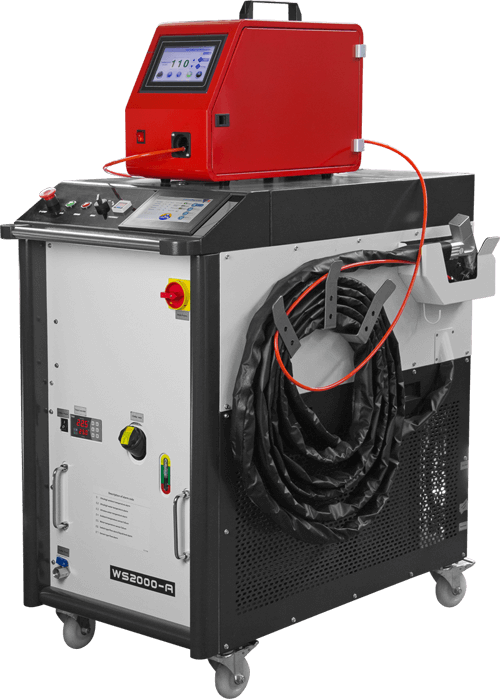

Hand lasers WS 1000/1500/2000 -A enable welding, cutting and cleaning of metal materials.

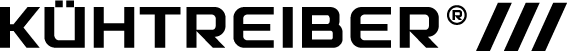

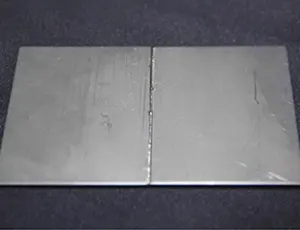

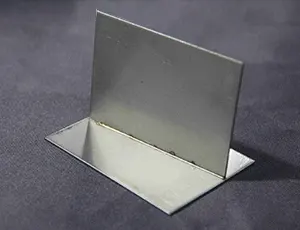

welding

cutting

cleaning

Features

- Adopting fiber laser generator, high optical power

density, high spot quality, stable output - Mainly used for welding of various metal sheet of the

same material or mixed materials, such as aluminium,

iron, stainless and copper sheets etc. - Adopting integrated design, small footprint and

convenient handling - Hand-held soldering head, ergonomic design, lightweight and practical

- Independent developed laser welding control system

with pulse and continuous modes - Small heat impact, small weld seam, strong welding

power, high precision welding quality, no need to polish - Easy to learn and use, with safety protection, no need

for experienced workers - Ultra-low operating cost

- Build in liquid cooling

- Protective gases – nitrogen, argon

| Type | Supply voltage | Laser power | Gross power | Overall dimension | Weight |

|---|---|---|---|---|---|

| WS1000 | 1x 230 V, 50/60 Hz | 1000 W | up to 7 kW | 580 x 1085 x 1125 mm | 245 kg |

| WS1500 | 1x 230 V, 50/60 Hz | 1500 W | up to 9 kW | 580 x 1085 x 1125 mm | 275 kg |

| WS2000 | 3x 400 V, 50/60 Hz | 2000 W | up to 10.5 kW | 580 x 1085 x 1125 mm | 290 kg |