STANDARD – No. 50032 | PROCESSOR – No. 50593 | SYNERGIC – No. 50307

MIG|MAG 3×400 V 30-350 A 40

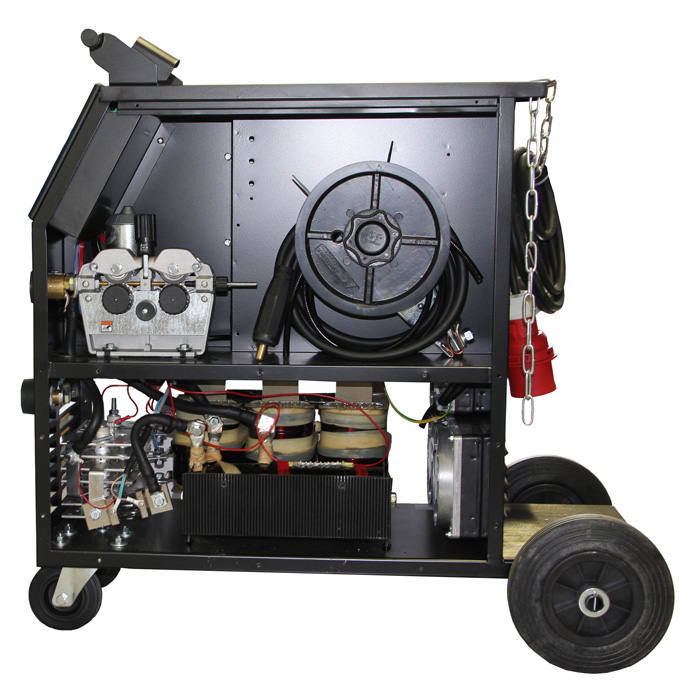

Compact three-phase MIG/MAG welding machines.

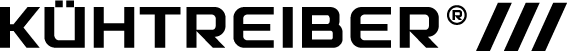

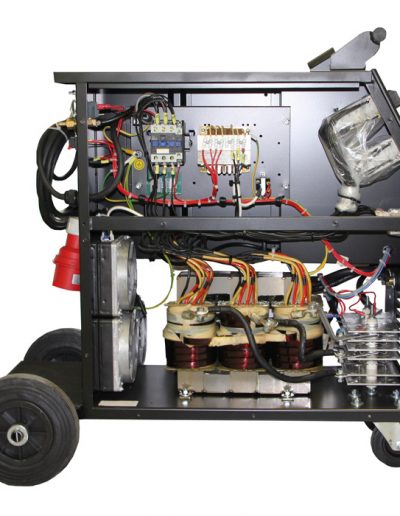

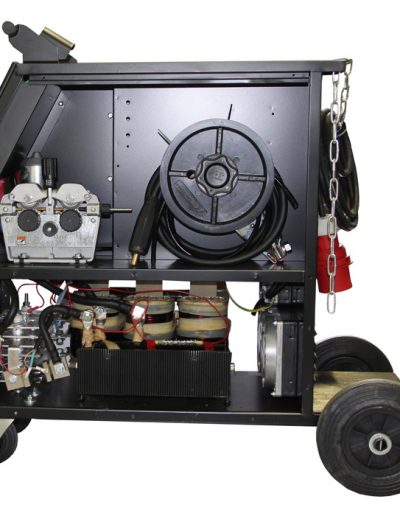

KIT 405 are professional welding machines equipped with a high-powered transformer with copper primary and secondary winding, robust all-metal wire feeder with an efficient motor, an EURO connector and electronics control.

The main advantages of machine KIT are excellent welding skills, 40-grade voltage control, high power, high duty cycle, high reliability and very easy operating of versions PROCESSOR and SYNERGIC.

In the case of Synergic machine there is, in addition, automatic adjustment of welding parameters and a possibility of programming. Standard equipment 8 programmes for standard steels (2 types of gas and 4 Ø of wire). A possibility of simple recording of your own programmes 40 – 60 welding parameters.

PROPERTIES AND EQUIPMENT

- 2-STROKE / 4-STROKE

- EASY USE

- SPOT PULS

- TEST GAS

- GENERATOR

- BURN BACK

- FEED BACK

- PRE-GAS / POST-GAS

- UP-DOWN (Processor/Synergic)

- SOFT START (Processor/Synergic)

- RESTORE PROGRAM (Synergic)

- JOB MODE (Synergic)

| Input power 50/60 Hz | 3x 400 V |

| Protection – slow | 25 A |

| Welding current range | 30 – 350 A |

| Output voltage range | 18 – 40 V |

| Duty cycle 100 % | 260 A |

| Duty cycle 60 % | 300 A |

| Duty cycle 30 % | 350 A |

| Mains current/input 60 % | 15.3 A / 10.6 KVA |

| Winding | Cu |

| Number of adjustment points | 40 |

| Digital volt-ampere meter | yes |

| Wire feeder | 4-roll |

| Standard equip roll | 1 – 1.2 |

| Wire feeder speed | 1 – 20 m/min |

| Material of wire – Steel, Stainless steel / Aluminium / Cored wire | yes |

| Ingress Protection | IP 21 |

| Dimensions | 806 × 490 × 822 mm |

| Weight | 101 kg |

STANDARD – No. 50032

PROCESSOR – No. 50593

SYNERGIC – No. 50307

KIT 405 are professional welding machines equipped with a high-powered transformer with copper primary and secondary winding, robust all-metal wire feeder with an efficient motor, an EURO connector and electronics control.

The main advantages of machine KIT are excellent welding skills, 40-grade voltage control, high power, high duty cycle, high reliability and very easy operating of versions PROCESSOR and SYNERGIC.

In the case of Synergic machine there is, in addition, automatic adjustment of welding parameters and a possibility of programming. Standard equipment 8 programmes for standard steels (2 types of gas and 4 Ø of wire). A possibility of simple recording of your own programmes 40 – 60 welding parameters.

PROPERTIES AND EQUIPMENT

- 2-STROKE / 4-STROKE

- EASY USE

- SPOT PULS

- TEST GAS

- GENERATOR

- BURN BACK

- FEED BACK

- PRE-GAS / POST-GAS

- UP-DOWN (Processor/Synergic)

- SOFT START (Processor/Synergic)

- RESTORE PROGRAM (Synergic)

- JOB MODE (Synergic)

| Input power 50/60 Hz | 3x 400 V |

| Protection – slow | 25 A |

| Welding current range | 30 – 350 A |

| Output voltage range | 18 – 40 V |

| Duty cycle 100 % | 260 A |

| Duty cycle 60 % | 300 A |

| Duty cycle 30 % | 350 A |

| Mains current/input 60 % | 15.3 A / 10.6 KVA |

| Winding | Cu |

| Number of adjustment points | 40 |

| Digital volt-ampere meter | yes |

| Wire feeder | 4-roll |

| Standard equip roll | 1 – 1.2 |

| Wire feeder speed | 1 – 20 m/min |

| Material of wire – Steel, Stainless steel / Aluminium / Cored wire | yes |

| Ingress Protection | IP 21 |

| Dimensions | 806 × 490 × 822 mm |

| Weight | 101 kg |